About us

History Emotions People Sustainability CertificationsAbout us

History

Founded in 1998 in Polverigi, Inoxa was born from a passion for metalworking and the founder Silvano Trombettoni's thirty years of experience. He aimed to create a company capable of meeting the design and functionality needs of home environments.

From the very beginning, the goal was clear: to create home solutions that simplify daily life while carefully and precisely responding to customer needs. Over time, our production has evolved, expanding from wire dish racks to a wide range of kitchen and home accessories, all with the same commitment to quality and design.

This approach has driven us to continually experiment and expand our product range, eventually adding new lines for the kitchen, bedroom, and bathroom, turning every project into a tangible response to household needs.

Today, Inoxa operates five production plants, covering a total of over 16,000 square meters in Polverigi, where all activities are managed—from production to logistics. These facilities are divided into two main hubs: one focused on technical production and the other on administration and logistics.

Our continuous growth and adaptability have established us as a benchmark in the industry. We have always invested in technology and in the expertise of our people, believing in uncompromising quality. In 2020, the ISO 9001 certification reaffirmed our commitment to consistent and verifiable quality, ensuring our customers receive safe, functional, and reliable products.

From a small business with 30 employees and a few production machines, Inoxa has grown to 100 employees, equipped with cutting-edge machinery and facilities.

Inoxa is founded

New facility in Via dell’Industria

Expansion of the production site

Establishment of a 1,500 sqm galvanic system

"Made in Italy" Certification

ISO 9001 Quality Management System Certification

Renovation of the Via dell’Industria facility facade

New 1,700 sqm facility + installation of solar panels

Emotions

Our value chain starts from steel wires and reaches people’s homes. We use innovative machinery and rely on skilled and passionate professionals. We work with different materials that merge to create products designed to improve everyday life.

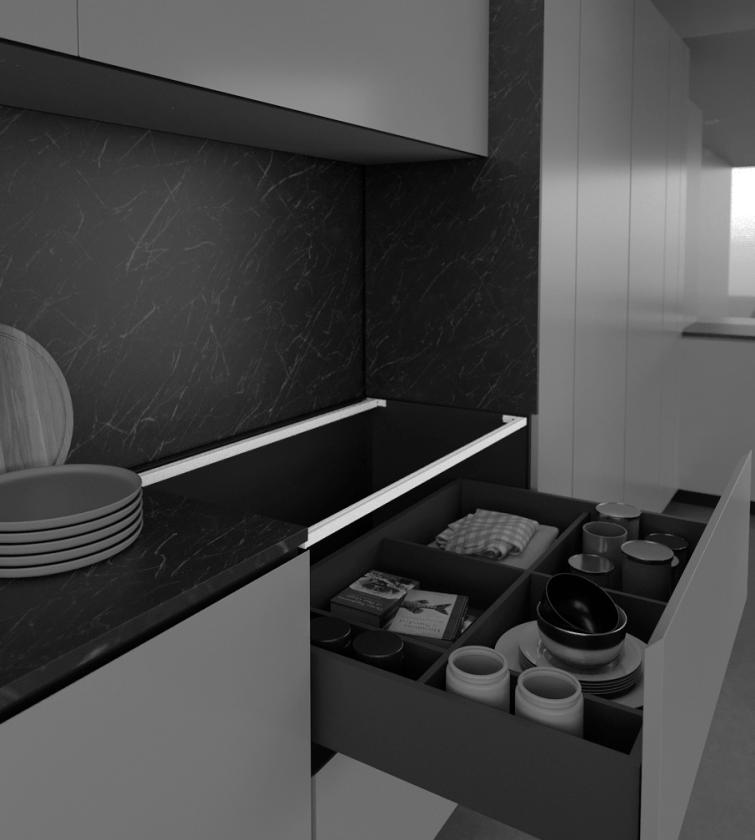

We see spaces as the result of the interaction between functionality and aesthetics, substance and form. We design kitchen accessories in steel wire, chrome-plated iron, and plastic, embodying the modern need to combine practicality, efficiency, and comfort with beauty.

Quality is not just a goal—it’s a habit. It is an approach that permeates the entire value chain: from the conception and design of a new product to its final use. We are guided by the commitment to finding solutions that enable people to make the most of their living spaces.

Quality is the result of ongoing dialogue and exchange with our customers. Innovation means engaging with new habits and needs to develop solutions that improve the way people experience their spaces.

We value knowledge and promote innovation. We do this to create ever-evolving solutions that merge design, functionality, and quality, meeting people’s changing needs.

Safety is one of our core values: safety in the workplace and in our processes, ensuring protection for people and the environment.

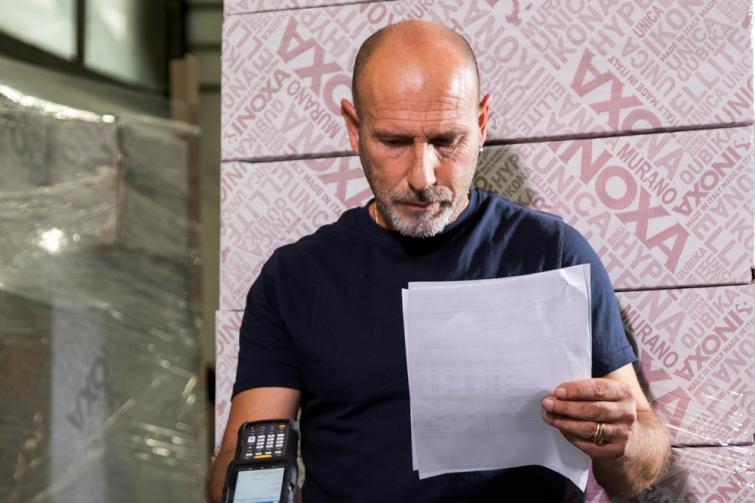

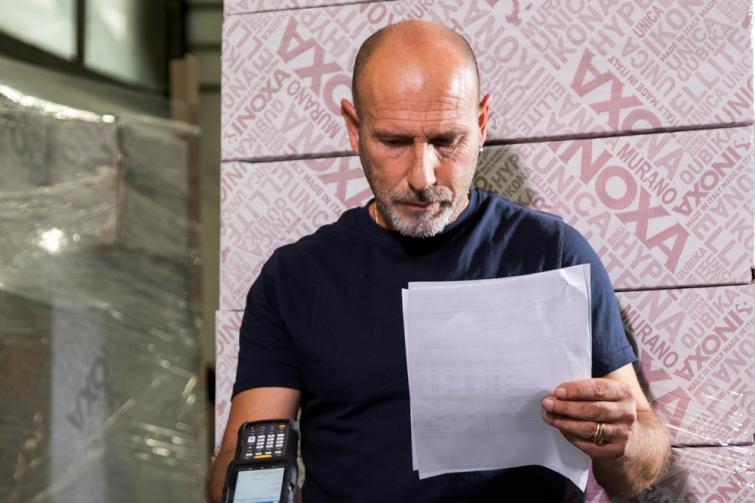

At Inoxa, human and technical expertise is the key to innovation. Our team consists of experienced professionals who constantly seek new paths and solutions. This continuous renewal allows us to develop innovative products and stay ahead of the industry.

People

We believe in the human value of work and in technology as a tool to enhance it. Our team consists of skilled professionals whose expertise interacts seamlessly with machines and equipment, ensuring that every production phase results in products that combine functional creativity, aesthetics, and practicality.

We are a company made of people who put quality at the center of everything they do, contributing daily to making Inoxa an innovative and customer-oriented business.

We believe human talent is fundamental to business success. Every one of our employees is an essential part of a process that blends creativity, precision, and technology. We continuously invest in training and development to ensure our team has the skills and tools needed to meet new challenges and respond to the evolving market.

Thanks to our people, our machinery operates daily, guided by the expertise of professionals. Thanks to them, our way of working comes to life—the way of those who know that new paths and solutions can be created every day.

Sustainability

The planet matters to us—the planet is us. We are committed to protecting the environment and the health of the people who inhabit it. For this reason, we partner with the best ISO 14000-certified suppliers, helping to reduce the environmental impact of our production processes.

Our chrome plating systems utilize innovative technologies that ensure safety for both people and the environment. With high productivity and zero pollution, thanks to closed-loop discharge systems, Inoxa products are coated with metallic chrome, which does not release harmful substances to humans or pollute nature.

We take pride in offering safe, durable products free of harmful materials, meeting our customers’ needs while improving household quality of life. Inoxa looks to the future with the goal of expanding its offerings and optimizing processes, never losing sight of the importance of a positive impact on the environment and people.

Among the most significant projects is the construction of our new production facility, designed with particular attention to reducing energy consumption and ensuring comfort for the people who work there every day.

The building, which covers an area of 1,686 m², was constructed using materials and solutions aimed at minimizing heat dispersion and optimizing energy use: from the roof covering to the lightweight wall panels, up to the shed windows designed to improve insulation both in winter and summer.

For heating, we chose a floor-based system divided into 6 independent zones, powered by a heat pump, ensuring targeted energy use and comfortable environments only where and when needed. The installation of fast-action doors on sectional gateways further helps reduce heat loss, preventing energy waste.

The new facility is also connected to our existing 140 kWp self-consumption photovoltaic system, which actively contributes to covering the company’s energy needs.

The expansion has also brought organizational and environmental benefits: bringing storage and shipping areas closer reduces internal material transfers, optimizes workflows, and improves the management of urgent tasks, with a positive impact on efficiency, lead times, and overall energy use.

Certifications

The choice of raw materials is a central aspect of our commitment to more responsible production.

For this reason, we have obtained FSC® certification, which verifies the use of wood-based materials and HPL sourced from certified supply chains, enhancing a controlled and transparent production chain (ask for FSC® certified products).

We have also obtained Product Carbon Footprint (CFP) certification for a selection of items representative of our premium range, with a focus on the Compact corner mechanisms [839BK/60AR, 839BY/60AR, 839BE/60CB, 839BE/60AR, 839B/60C, 839B/60AR, in all three mechanism versions: Low, Medium, High] and Combi’s [846BE/DX60CB, 846BE/DX60AR, 846BYAS/DX60AR]. These are functional solutions to which we have chosen to attribute an additional level of value by obtaining Carbon Footprint certification, which measures and verifies their environmental impact throughout their entire life cycle.

The data obtained represents a concrete starting point for identifying areas for improvement and guiding increasingly sustainable design choices.

We uphold a strong and consistent commitment to proven quality: our ISO 9001 Quality Management System certification ensures structured processes, meticulous controls, and a culture of continuous improvement across every stage of production.

Our manufacturing is entirely Made in Italy—a hallmark that represents far more than geographic origin. It embodies care, expertise, a fully monitored supply chain, attention to materials, and authentic industrial craftsmanship. Each product is born from deep-rooted technical know-how and an innovative design mindset that elevates local tradition, turning it into contemporary and reliable solutions.