Magazine

< back

Interview with Franco Crispiani, Warehouse Worker

We interviewed Franco Crispiani, who told us about his job as a warehouse worker at Inoxa.

-

Can you tell us about your role at Inoxa and what the main responsibilities of a warehouse worker are?

My role is that of a forklift warehouse operator. I mainly handle the transfer of materials between the company's various storage facilities, the unloading of goods, and the related qualitative and quantitative inspection of the products supplied by our vendors. -

What does a typical workday look like for you, and what are the most common challenges you face?

My day begins with transferring goods between warehouses and inspecting incoming materials, which are then identified and properly stored. Every day is different, even though I always plan my tasks to manage them as effectively as possible. Still, there are always small unexpected issues that require readiness and flexibility. -

The warehouse is often considered the beating heart of a company. How important is organization, and what tools or methods do you use to keep things in order?

Organization is essential. I’ve set up a dedicated space for the initial storage of incoming goods, so I can check them before placing them in more strategic locations. Each pallet is clearly labeled using A4 sheets with barcodes to ensure immediate and accurate traceability of stock. -

How crucial is teamwork in the warehouse, and how do you collaborate with other departments?

Collaboration is key, especially with my fellow warehouse workers, as constant coordination is needed to work efficiently together. There’s ongoing communication with the heads of other departments as well, supported by the company’s management system, which facilitates real-time information sharing. -

Over time, have you seen changes in how the warehouse is managed? Are there any innovations or improvements that have made your work more efficient?

Yes, the warehouse is constantly evolving. We've optimized space with shelving tailored to pallets type, distinguishing areas for fast-moving products from those intended for long-term storage. This has allowed us to speed up operations and streamline workflows. -

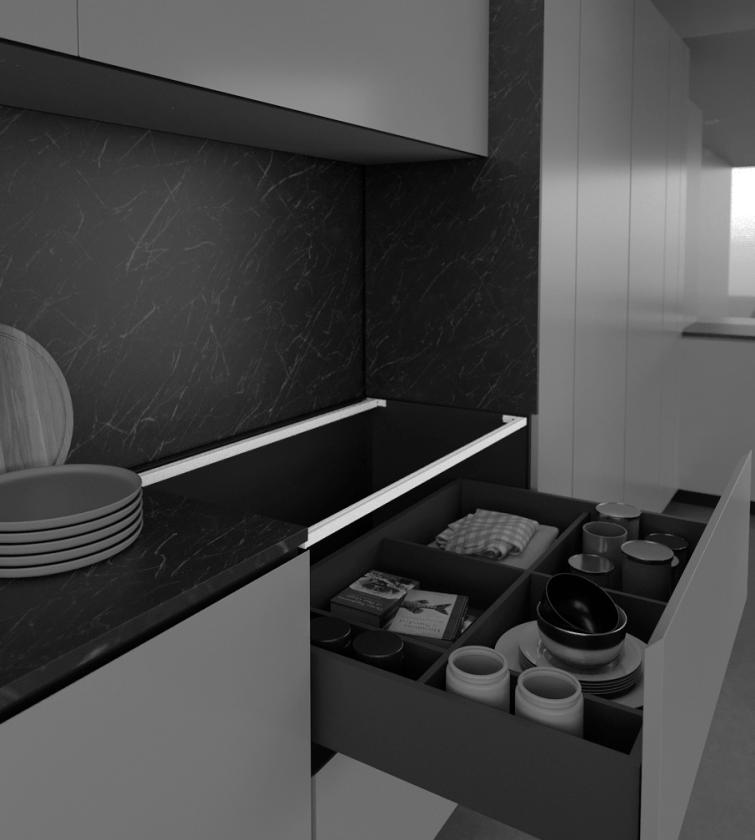

Among the many Inoxa products you handle daily, is there one that has impressed you particularly in terms of design or functionality?

I’m always fascinated by the continuous research and development of new products. In particular, I really appreciate the refined design of our aluminum and sheet metal collections—the attention to detail and the distinctive elegance that make these collections truly unique. -

What has been the most complex situation you’ve faced in your job, and how did you resolve it?

Challenges are always present, and it often feels like a real race against time. In those moments, it’s essential to stay clear-headed and calm to ensure both workplace safety and the integrity of the goods. Experience has taught me that thinking before acting is the key to handling any situation in the best possible way. -

What gives you the most satisfaction in your job, and what makes you proud to be part of Inoxa?

I spend most of my day at the company and always strive to give my best, collaborating with colleagues and facing daily challenges with seriousness and a smile.

What makes me most proud to work here is knowing I’m part of a united and reliable team.